Welding helmets are a vital part of protective equipment for every welder, providing comprehensive protection for the face, neck, and eyes against harmful factors generated during welding work. They are essential for shielding against the intense light of the welding arc, sparks, molten metal splashes, and hazardous radiation, which can cause permanent eye damage.

Where Are Welding Helmets Used?

Welding helmets are widely used across various industrial and workshop settings. In the automotive and construction sectors, they are standard equipment for welders joining metal structures. They are necessary for all common welding methods, including MIG/MAG, MMA, and TIG welding, each requiring appropriate protection against specific hazards.

In industrial environments, welding helmets are used in poorly ventilated spaces, on construction sites, and in workshops with unstable power supplies. Multifunctional models provide protection not only during welding but also during metal cutting and grinding, making them a versatile tool in any metalworking facility.

Applications also include hobby and home projects, where occasional users need reliable protection during smaller welding tasks. Training institutions use them for safely teaching welding techniques, ensuring students are properly protected during practice.

Why Use Professional Welding Helmets?

The main advantage of welding helmets is comprehensive protection for the welder’s health. They protect against direct contact with sparks and molten metal splashes that can cause severe skin burns. Equally important is eye protection from intense light and harmful UV radiation emitted by the welding arc.

Modern auto-darkening helmets greatly improve comfort by eliminating the need to repeatedly lift and lower the helmet during welding. The auto-arc detection and adjustable shade features allow the helmet to adapt to changing lighting conditions and welding intensity.

Models with ventilation systems provide cleaner air and reduce fatigue during long work sessions, especially important for professional welders working in multi-shift schedules. Ergonomic designs with adjustable head straps ensure a stable and secure fit.

Work efficiency is significantly increased thanks to lift-up visors that allow weld progress checks without removing the entire helmet. Interchangeable lenses with different shade levels enable customization to the specific welding task and method.

How to Properly Maintain a Welding Helmet?

Proper maintenance of welding helmets is crucial to preserve their protective properties and extend their lifespan. Regular cleaning of protective lenses, inspection of headgear components, and replacement of worn parts ensure continuous safety during welding operations.

Types of Welding Helmets Available

Passive (manual) helmets are traditional models with a fixed lens shade. They are lightweight, economical, and equipped with interchangeable filters of varying darkness. Most modern passive models feature flip-up visors, allowing weld inspection without removing the helmet.

Auto-darkening helmets represent the most advanced technology with filters that automatically adjust the lens shade. Sensors detect the welding arc and instantly darken the lens. For MIG/MAG and MMA methods, helmets with two sensors are sufficient, offering adjustable shade levels to suit varying work conditions.

Helmets with ventilation systems are specialized solutions that provide improved air circulation, especially useful for professional welders working in poorly ventilated environments. They ensure high-quality air and reduce fatigue during prolonged tasks.

Multifunctional welding helmets offer universal protection for welding, cutting, and grinding. Adjustable protective parameters make them a cost-effective choice for workshops performing diverse metalworking operations.

PATON – Your Comprehensive Partner in Welding

In addition to high-quality welding helmets in our range, PATON offers a full range of professional welding equipment. Combining over 60 years of scientific heritage with modern digital inverter technologies, we create reliable solutions for professionals.

Our main range includes advanced inverter welders of all types: MMA welders for manual arc welding with coated electrodes, MIG/MAG semi-automatic welders for gas-shielded welding, and TIG devices for precise TIG Lift welding. Multiprocessing welders combine MMA, MIG/MAG, and TIG Lift in one unit, offering maximum versatility.

The PATON welding machine range includes the main series: MINI for home users and small installation jobs, ECO series — a semi-professional line for MMA welding, StandardMIG semi-automatic series for workshops and professionals with a PULSE function, and PROFESSIONAL series for heavy industry with machines up to 630A.

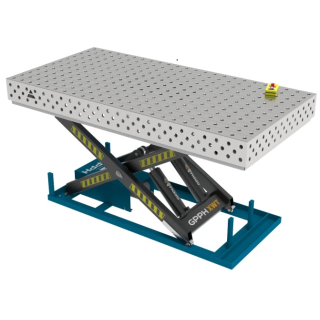

We also offer supplementary equipment such as wire feeders, plasma cutters, autonomous cooling units, and micro-welding tools. The range is complemented by consumables — high-quality electrodes and welding wire.

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)