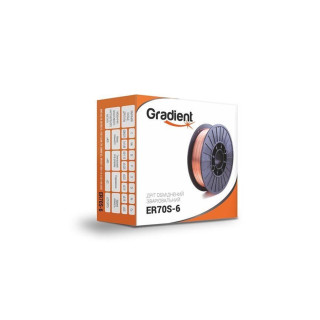

Wire feeders are devices designed to provide uninterrupted supply of flux-cored or solid wire to the welding zone. They are necessary when welding metals in MIG mode. Sometimes they are included in the welding machines themselves, but it is much more convenient if the wire feeder is placed in a separate housing. This increases mobility when using welders and makes it easier to work with metal.

Each wire feeder consists of a drive motor and a system of coils that direct the consumable to the welding zone. The unit must ensure that the wire is fed evenly at the optimum pressure. If the pressure is too high, the wire can be deformed.

Advantages of Paton wire feeders

Paton digital welding wire feeders are used in conjunction with a separate welding power source. They ensure that the wire moves gradually into the weld zone in semi-automatic welding mode. They can be used with both solid and flux-cored wire.

Our brand wire feeders offer the following advantages:

• own inverter power source;

• metal mechanism with a sealed motor;

• connection to a welding machine using a torch and a EURO-type connector;

• a digital board that automatically receives signals via the "EURO" connector and supplies consumables according to the specified control settings;

• rollers push the wire at a pressure and speed suitable for obtaining a high-quality weld seam even with little welding experience.

Using Paton wire feeders

Paton wire feeders are suitable for our brand of inverters and semi-automatic machines that can operate in MIG mode. The wire feeders are fully optimized for their use and are ideal for semi-automatic metal welding. You can also use them when working with welding inverters from other manufacturers that are equipped with a EURO connector.

Where can I buy Paton wire feeders?

You can buy Paton wire feeders right on this page of our catalog. All models that are in stock are presented here, as well as current prices and discounts for them. You can buy a wire feeder in one click from the product page or view full information about each model there. Buy Paton products to get high-quality equipment for metal welding at home, on construction sites and for industrial purposes!

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)