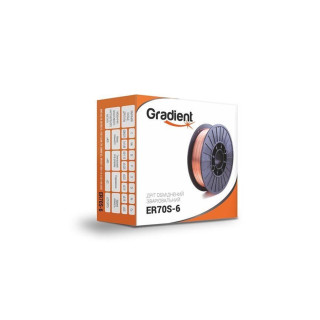

Copper-cored welding wire is a consumable used in semi-automatic welding machines. It has several advantages over non-copperized wire. To apply a copper coating to steel, the wire is immersed in a solution of copper sulfate. This leads to a substitution process, during which iron particles are transferred to the solution and a small layer of copper appears in their place. After being run through the wire, the copper is compacted, and the surface of the wire becomes glossy and has a characteristic pinkish tint.

Advantages of copper-plated Paton wire

• Paton copper-clad welding wire can be used for automatic and semi-automatic metal welding. It is widely used in shipbuilding and machine building, as well as in construction projects of various sizes. It provides a strong connection between metal parts and has the following advantages:

• The use of a copper coating reduces resistance, which significantly increases current conductivity, ensuring a uniform arc and high quality weld.

• The low contact resistance makes it possible to weld metal with virtually no spatter, which increases safety and saves materials.

• The high tensile strength allows the use of filler wire with automatic feeders without deforming the consumable.

Where to buy copper-cored welding wire Paton?

You can buy Paton copper-clad welding wire directly on this page of our online store. Choose the appropriate coil weight and wire diameter to get a high-quality consumable for semi-automatic or automatic welding. Choose a wire of our brand to get a high-quality weld seam at the best price.

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)