Automatic control units are advanced electronic systems designed to monitor, control, and manage critical industrial processes. ATS (Automatic Train Supervision) and ABP (Automatic Train Protection) systems represent the highest level of technology in safety automation, ensuring reliable operation in the most demanding railway and industrial environments.

Main Areas of Application for ATS and ABP Technology

Automatic control units are widely used in key sectors where safety and reliability are a priority. In railway transport, ABP systems monitor driver alertness through an active vigilance device and enable immediate response in emergencies via the Radiostop system.

Rail networks utilize these advanced systems to secure traffic on main and regional lines. ATS systems are essential in railway traffic control centres, where automatic supervision allows monitoring and restricting train movement permissions in specific areas.

In heavy industry, automatic control units ensure continuity of production processes in metallurgical, chemical, and energy plants. These systems are also critical in infrastructure such as power plants, refineries, and energy distribution centres, where automatic switching and control are necessary to maintain uninterrupted operations.

Benefits of Automatic Control Systems

The primary advantage of ATS and ABP systems is significantly enhanced operational safety by minimizing human error. Automatic driver vigilance monitoring and parameter supervision ensure that trains do not exceed permitted speeds or pass a “STOP” signal, which is essential for the safety of passengers and cargo.

Immediate response in emergencies through the Radiostop system enables automatic braking of all trains in the affected area. This functionality is invaluable in case of track obstacles, derailments, or other safety hazards.

These systems also provide substantial operational savings through energy-efficient driving and optimal braking, reducing operating costs. Automatic control allows precise stopping at stations and efficient train operation according to the schedule.

Compliance with international standards, including the European ETCS system, ensures interoperability between different railway systems in European countries, which is crucial for international rail transport.

Service and Maintenance Considerations

Automatic control units require specialized service by certified technical personnel only. These systems undergo mandatory periodic inspections according to schedules outlined in technical-operational documentation, ensuring reliability and compliance with railway safety regulations. Regular computer diagnostics and software updates must be performed exclusively at authorized service centres.

Explore the Diversity of Automatic Control Systems

Automatic control units can be classified by level of sophistication and functionality. Basic ABP systems include an active vigilance device monitoring driver alertness and a Radiostop system for emergency train stops.

Advanced ATP (Automatic Train Protection) systems automatically limit train speed by continuously comparing actual speed with safe speed limits. ATO (Automatic Train Operation) systems enable fully automatic train control, including start-up, constant-speed operation, and precise braking.

According to ETCS (European Train Control System) levels, systems range from Level 0 to Level 3, with each level offering higher automation. Level 2 uses continuous GSM-R radio communication, while Level 3 eliminates the need for traditional track circuits through advanced train location systems.

Modern CBTC (Communications-Based Train Control) systems represent the highest automation level, providing full control of urban rail and metro lines, where high frequency and precise train management are required.

Why Choose PATON Products?

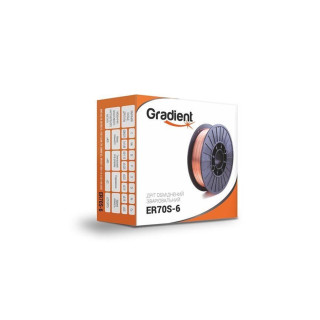

PATON, with over 60 years of experience and the scientific heritage of the E.O. Paton Electric Welding Institute, is a recognized leader in welding equipment. While automatic control units complement our main welding product line, we offer them as part of comprehensive industrial auxiliary equipment

Our core portfolio includes high-quality inverter welders:

MINI Series – compact MMA welders with 150A current, ideal for home users and small workshops, featuring Hot-Start, Anti-Stick, and Arc-Force functions.

StandardMIG Series — multifunctional single-body semi-automatic machines for MIG/MAG/TIG/MMA welding with a PULSE function.

ProMIG Series — a professional series (200A–630A) designed for intensive use.

PATON welding machines come with a warranty of up to 5 years. The equipment meets international standards. By choosing PATON, you receive technologies based on scientific achievements and proven by thousands of satisfied customers.

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)