-

- Type of oil non-synthetic

- Viscosity type SAE 10W-30

- Volume 1 l

-

- Equipment instructions, warranty card, ATS to generator connection cable (8 m)

- Power up to 10,000 W

- Supply voltage 220 V

- Additionally sensors for monitoring input/output voltage, load, battery charge, overload protection, emergency shutdown button, operation error indicator

- Current strength up to 45 A

- Weight 6.3 kg

-

- Equipment Automation unit, Connection cable – 3 meters

- Power 7 kW

- Supply voltage U 1 ~ 230 ± 10% V

- Weight 5,05 kg

-

- 13189 грн

- Body material metal

- Equipment generator connection cable (8 m), warranty card, packaging

- Power 20000 W - 32000 W

- Supply voltage 380 V

- Number of phases 3

- Additionally sensors for monitoring input/output voltage, load, battery charge, overload protection, emergency shutdown button, operation error indicator

-

- Fuel tank 6,5 liters

- Fuel type Gasoline

- Gross weight 22,7 kg

- Height 450 mm

- Length 405 mm

- Operating time at 2/3 load 5.4 hours

- Tool weight 20,6 kg

- Width 395 mm

- Noise level 95 dB

- Number of 230 V sockets 1

- Output power (S1) at 230 V 1000 W

- Max. engine power 1400 W

- Max. output power (S2) at 230 V 1100 W

- Rated current at 230 V 4,35 А

-

- 13499 грн

- Fuel tank 12 l

- Fuel type Gasoline

- Gross weight 39.7kg

- Noise level 71/96 dB

- Number of 230 V sockets 2

- Max. engine power 2.8 kW

- Alternator type Copper

- Rated output power 2.5

- Supply voltage 230 V

- Frequency 50 Hz

- Engine type Gasoline, 4-stroke

- Engine model KSB 220

- Engine displacement 210 cm3

- Olive tank volume 0.6 l

- Start type Manual

- Current strength 12.17 А

- Power factor (cos Φ) 1

- Protection / sensors IP23M

- Overall dimensions 605x440x435 мм

- Weight 36.6 kg

-

- Fuel tank 15 liters

- Gross weight 39,5 kg

- Height 460 mm

- Length 605 mm

- Operating time at 2/3 load 12,5 hours

- Tool weight 37 kg

- Width 460 mm

- Noise level 96 dB

- Number of 230 V sockets 2

- Output power (S1) at 230 V 2100 W

- Max. engine power 4150 W

- Max. output power (S2) at 230 V 2400 W

- Rated current at 230 V 9,1 А

-

- Fuel tank 15 liters

- Gross weight 44,6 kg

- Height 455 мм

- Length 603 мм

- Operating time at 2/3 load 10,7 hours

- Tool weight 42,1 kg

- Width 475 мм

- Noise level 96 dB

- Number of 230 V sockets 2

- Output power (S1) at 230 V 2600 V

- Max. engine power 4100 W

- Max. output power (S2) at 230 V 2800 W

- Rated current at 230 V 11,3 А

-

- Fuel tank 15 l

- Fuel type Gas/petrol

- Gross weight 47.5kg

- Noise level 68/93 dB

- Number of 230 V sockets 2

- Max. engine power 2.9 kW

- Alternator type Aluminum

- Rated output power 2.5

- Supply voltage 230 V

- Frequency 50 Hz

- Engine type Gas/petrol 1-cylinder, 4-stroke, air-cooled

- Engine model KS 200

- Engine displacement 196 cm3

- Hours of work 15 hours (at 50% load)

- Olive tank volume 0.6 l

- Start type Manual

- Display Hour meter, frequency, voltage

- Current strength 12.5 А

- Power factor (cos Φ) 1

- Protection / sensors IP23M

- Overall dimensions 610x455x485 мм

- Weight 43 kg

-

- Alternator type inverter with copper winding

- Maximum output power 2300 W

- Rated output power 1800 W

- Supply voltage 230 V

- Frequency 50 Hz

- Number of phases 1

- Engine type gasoline (5-8% more powerful engine compared to engines with identical parameters)

- Engine brand 4-х тактный 1-цилиндровый OHV

- Cooling system air

- Engine displacement 79 cc

- Burning tank volume 4.2 L

- Hours of work 5.5 hours (at 50% load)

- Olive tank volume 0.38 L

- Start type manual

- Additionally reduced fuel usage and economical generator operation minimizes wear and tear, dual fuel system, high quality electrical energy, minimized emissions, resistant to external influences, low noise level, small size

- Overall dimensions 575×375×555 мм

- Weight net 23 kg / gross 25 kg

-

- Engine power 2.5 hp

- Alternator type Copper

- Maximum output power 2 kW

- Rated output power 1.8 kW

- Frequency 50

- Number of phases 1

- Engine type gasoline 1-cylinder, 4-stroke, air-cooled

- Engine model KS 110i

- Engine displacement 79.7 cc

- Burning tank volume 5 L

- Hours of work at 50% load - 6.25

- Olive tank volume 0.4 L

- Start type manual

- Display Motor cycle, frequency, voltage

- Power factor (cos Φ) 1

- Protection / sensors IP23M

- Noise level 62/87

- Overall dimensions 500x285x460

- Weight 19 kg

-

- Engine power 3.3 hp

- Maximum output power 2 kW

- Rated output power 1.8 kW

- Frequency 50

- Number of phases 1

- Engine type gasoline 1-cylinder, 4-stroke, air-cooled

- Engine brand KS 110i

- Engine displacement 79.7 cc

- Burning tank volume 4 L

- Olive tank volume 0.35 L

- Start type manual

- Display Motor cycle, frequency, voltage

- Power factor (cos Φ) 1

- Protection / sensors IP23M

- Noise level 62/95

- Overall dimensions 510x320x475

- Weight 21.2 kg

-

- 31099 грн

- Fuel tank 25 l

- Fuel type Gasoline

- Gross weight 68.6 kg

- Noise level 72/97 dB

- Number of 230 V sockets 2

- Alternator type Copper

- Maximum output power 5.5 кВт

- Rated output power 5 кВт

- Power 15

- Supply voltage 230 V

- Frequency 50 Hz

- Engine type Gasoline, 4-stroke

- Engine model KSB 440

- Engine displacement 420 cm3

- Burning tank volume 25 l

- Hours of work at 50% load - 9 hours

- Olive tank volume 1.1 l

- Start type Manual

- Power factor (cos Φ) 1

- Protection / sensors IP23M

- Overall dimensions 690х525х550 мм

- Weight 66.6 kg

-

- Fuel tank 25 liters

- Gross weight 86,5 kg

- Height 582 mm

- Length 719 mm

- Operating time at 2/3 load 11,7 hours

- Tool weight 82,8 kg

- Width 565 mm

- Noise level 96 dB

- Number of 230 V sockets 2

- Output power (S1) at 230 V 3000 W

- Max. engine power 7500 W

- Max. output power (S2) at 230 V 3300 W

- Rated current at 230 V 13 А

-

- Fuel tank 25 l

- Fuel type Gasoline

- Gross weight 78.6 kg

- Noise level 70/95 dB

- Number of 230 V sockets 1

- Alternator type Copper

- Rated output power 5

- Power 5.5 kW

- Supply voltage 230 V

- Frequency 50 Hz

- Engine type Gasoline 1-cylinder, 4-stroke, air-cooled

- Engine model KS 390

- Engine displacement 389 cm3

- Hours of work 17 hours (at 50% load)

- Olive tank volume 1.1 l

- Start type Manual/electric

- Current strength 23.91 А

- Power factor (cos Φ) 1

- Protection / sensors IP23M

- Overall dimensions 700x545x590 мм

- Weight 76.2 kg

-

- Fuel tank 4,2 liters

- Fuel type Gasoline/gas

- Gross weight 27,1 kg

- Height 600 mm

- Length 575 mm

- Operating time at 2/3 load 5,9 hours

- Tool weight 23,7 kg

- Width 380 mm

- Noise level 95 dB

- Number of 230 V sockets 2

- Output power (S1) at 230 V 1800 W

- Max. engine power 2300 W

- Max. output power (S2) at 230 V 1900 W

- Rated current at 230 V 7,8 А

- Maximum output power 1700 Wt

- Rated output power 1600 Wt

-

- Fuel consumption 1.67 l/h

- Maximum power 1f 3.5 kW

- Nominal power 1f 3.2 kW

- Alternator type synchronous

- Power 3.2 kW

- Supply voltage 220 V

- Frequency 50 Hz

- Number of phases 1

- Engine type 4-stroke

- Engine model Rato R210 D-Vi

- Cooling system air

- Engine displacement 212 cm3

- Burning tank volume 8.3 L

- Hours of work 8.0 hours

- Olive tank volume 0.5 L

- Start type Electric starter, Manual

- Additionally USB output, Parallel connection

- Noise level 91 dB

- Overall dimensions 59x45.6x51 см

- Weight 45.0 kg

-

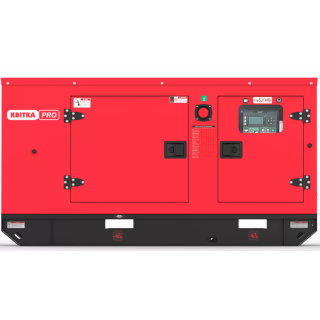

- Degree of protection IP54

- Alternator type synchronous with copper winding

- Maximum output power 40000 Вт

- Rated output power 36000 Вт

- Supply voltage 230 В / 380 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Cooling system liquid

- Engine displacement 4484 cc

- Burning tank volume 135 L

- Start type electric starter / AVR

- Noise level 70 дБ

- Overall dimensions 1770х850х1440 мм

- Weight 1440 кг

-

- Degree of protection IP23

- Alternator type synchronous with copper winding

- Maximum output power 44000 Вт

- Rated output power 40000 Вт

- Supply voltage 230 В / 380 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Cooling system liquid

- Engine displacement 3857 cc

- Burning tank volume 225 L

- Start type electric starter / AVR

- Overall dimensions 2225x950x1640 мм

- Weight 1250 кг

-

- Degree of protection IP23

- Alternator type synchronous with copper winding

- Maximum output power 52800 Вт

- Rated output power 48000 Вт

- Supply voltage 230 В / 380 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Cooling system liquid

- Engine displacement 2900 cc

- Burning tank volume 90 L

- Start type electric starter / AVR

- Overall dimensions 2300х1260х1000 мм

- Weight 1250 кг

-

- Degree of protection IP23

- Alternator type synchronous with copper winding

- Maximum output power 70400 Вт

- Rated output power 64000 Вт

- Supply voltage 230 В / 380 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Cooling system liquid

- Engine displacement 4500 cc

- Burning tank volume 90 L

- Start type electric starter / AVR

- Overall dimensions 2650х1460х1100 мм

- Weight 1450 кг

-

- Degree of protection IP54

- Alternator type synchronous with copper winding

- Maximum output power 57600 Вт

- Rated output power 52000 Вт

- Supply voltage 230 В / 380 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Cooling system liquid

- Engine displacement 4400 cc

- Burning tank volume 220 L

- Start type electric starter / AVR

- Noise level 70 дБ

- Overall dimensions 2440x1000x1860 мм

- Weight 1440 кг

-

- Degree of protection IP33

- Alternator type synchronous with copper winding

- Maximum output power 35 кВт / 44 кВА

- Rated output power 32 кВт / 40 кВА

- Supply voltage 230 / 400 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Engine brand YuChai

- Engine model YCD4V22D-55/YC4V55Z-D20

- Cooling system liquid

- Engine displacement 4214 cc

- Burning tank volume 80 L

- Hours of work 10 hours (at 50% load)

- Olive tank volume 6 л

- Start type electric start / there is an output for ATS

- Voltage stabilization intelligent AVR system

- Additionally diesel fuel heating system

- Display LED/DC42D: oil pressure, water temperature, engine speed, battery voltage, frequency

- Current strength 57.6 А

- Power factor (cos Φ) 0.8

- Protection / sensors oil pressure, coolant temperature, engine speed, overload (current)

- Noise level 79 дБ

- Overall dimensions 2100x900x1150 мм

- Weight 930 кг

-

- Degree of protection IP33

- Alternator type synchronous with copper winding

- Maximum output power 35 кВт / 44 кВА

- Rated output power 32 кВт / 40 кВА

- Supply voltage 230 / 400 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Engine brand Cummins

- Engine model 4BT3.9-G2

- Shaft rotation speed 1500 об/хв

- Cooling system liquid

- Engine displacement 3900 сс

- Burning tank volume 80 L

- Hours of work 10 hours (at 50% load)

- Olive tank volume 6 л

- Start type electric start / there is an output for ATS

- Voltage stabilization intelligent AVR system

- Additionally diesel fuel heating system

- Display LED/DC42D: oil pressure, water temperature, engine speed, battery voltage, frequency

- Current strength 57.6 А

- Power factor (cos Φ) 0.8

- Protection / sensors oil pressure, coolant temperature, engine speed, overload (current)

- Noise level 79 дБ

- Overall dimensions 2200х900х1150 мм

- Weight 1340 кг

-

- Degree of protection IP33

- Alternator type synchronous with copper winding

- Maximum output power 88 кВт / 110 кВА

- Rated output power 80 кВт / 100 кВА

- Power 136 к.с.

- Supply voltage 230 / 400 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Engine brand YuChai

- Engine model YC4A140L-D25

- Cooling system liquid

- Engine displacement 4840 cc

- Burning tank volume 200 L

- Hours of work 10 hours (at 50% load)

- Olive tank volume 11.5 л

- Start type electric start / there is an output for ATS

- Voltage stabilization intelligent AVR system

- Display LED/DC42D: oil pressure, water temperature, engine speed, battery voltage, frequency

- Current strength 144 А

- Power factor (cos Φ) 0.8

- Protection / sensors oil pressure, coolant temperature, engine speed, overload (current)

- Noise level 79 дБ

- Overall dimensions 2750х1000х1370 мм

- Weight 1300 кг

-

- Degree of protection IP33

- Alternator type synchronous with copper winding

- Maximum output power 88 кВт / 110 кВА

- Rated output power 80 кВт / 100 кВА

- Power 125 к.с.

- Supply voltage 230 / 400 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Engine brand Cummins

- Engine model 6BT5.9-G2

- Cooling system liquid

- Engine displacement 5900 cc

- Burning tank volume 200 L

- Olive tank volume 11.5 л

- Start type electric start / there is an output for ATS

- Voltage stabilization intelligent AVR system

- Display LED/DC42D: oil pressure, water temperature, engine speed, battery voltage, frequency

- Current strength 144 А

- Power factor (cos Φ) 0.8

- Protection / sensors oil pressure, coolant temperature, engine speed, overload (current)

- Noise level 79 дБ

- Overall dimensions 2750х1000х1370 мм

- Weight 1500 кг

-

- Degree of protection IP33

- Alternator type synchronous with copper winding

- Maximum output power 132 кВт / 165 кВА

- Rated output power 120 кВт / 150 кВА

- Supply voltage 230 / 400 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Engine brand YuChai

- Engine model YC6B205L-D20

- Cooling system liquid

- Engine displacement 7700 cc

- Burning tank volume 280 L

- Olive tank volume 15 л

- Start type electric start / there is an output for ATS

- Voltage stabilization intelligent AVR system

- Additionally diesel fuel heating system

- Display LED/DC42D: oil pressure, water temperature, engine speed, battery voltage, frequency

- Current strength 216 А

- Power factor (cos Φ) 0.8

- Protection / sensors oil pressure, coolant temperature, engine speed, overload (current)

- Noise level 79 дБ

- Overall dimensions 3510х1305х1850 мм

- Weight 1500 кг

-

- Degree of protection IP33

- Alternator type synchronous with copper winding

- Maximum output power 132 кВт / 165 кВА

- Rated output power 120 кВт / 150 кВА

- Power 211 к.с.

- Supply voltage 230 / 400 В

- Frequency 50 Hz

- Number of phases 1 / 3

- Engine type diesel

- Engine brand Cummins

- Engine model 6BTAA5.9-G12

- Cooling system liquid

- Engine displacement 5900 cc

- Burning tank volume 280 L

- Olive tank volume 15 л

- Start type electric start / there is an output for ATS

- Voltage stabilization intelligent AVR system

- Additionally diesel fuel heating system

- Display LED/DC42D: oil pressure, water temperature, engine speed, battery voltage, frequency

- Current strength 216 А

- Power factor (cos Φ) 0.8

- Protection / sensors oil pressure, coolant temperature, engine speed, overload (current)

- Noise level 79 дБ

- Overall dimensions 3300х1300х1800 мм

- Weight 1885 кг

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)