Oil-free compressors are modern air-compressing devices that operate without oil in the compression chamber, delivering 100% clean air free from oil contamination. Thanks to specialized construction materials and advanced technologies, oil-free compressors are an ideal solution for industries requiring the highest quality compressed air. These innovative devices eliminate the risk of oil particles entering pneumatic systems, ensuring the safety of production processes.

Where Are Oil-Free Compressors Used?

Oil-free compressors are widely used in industries where air purity is critical for safety and process quality. In the medical and pharmaceutical sectors, these compressors power respirators, dental tools, sterilization systems, and equipment for drug production, where even minimal oil contamination is unacceptable.

The food and beverage industry uses oil-free compressors for packaging, bottling, pneumatic transport of ingredients, and equipment cleaning. In scientific laboratories, they power analytical instruments, chromatographs, and mass spectrometers, providing ultra-clean air necessary for precise research.

In the electronics industry, oil-free compressors are used for assembling and testing delicate components, where air purity directly affects product quality. Paint workshops employ these devices in spray booths to prevent surface defects. Small oil-free compressors are also popular in hobby applications, modelling, and airbrushing.

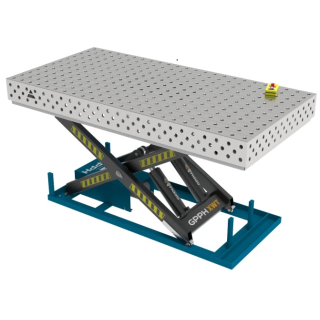

Oil-free compressors in welding provide clean, oil-free air needed for joint preparation and blow-off before welding, especially in precision aluminum and stainless steel welding. They power pneumatic light tools used in joint processing and ventilation/extraction systems, eliminating the risk of oil contamination that could compromise weld quality.

Why Choose an Oil-Free Compressor?

The main advantage of oil-free compressors is the delivery of pure compressed air with virtually zero oil content. This feature is crucial in industries with high hygiene standards, eliminating the risk of contaminating end products and technological processes.

Significant cost savings result from eliminating the need for advanced oil filters and their regular replacement. Oil-free compressors also have simplified maintenance requirements since they do not require regular oil changes, reducing service costs and downtime.

Environmental friendliness is another key advantage — no used oil means less waste for disposal and no risk of oil leaks. These compressors also operate quietly (especially rotary screw models), which is important in offices, laboratories, and medical settings.

High operational reliability comes from using specialized self-lubricating materials, such as Teflon composites or ceramic coatings. Eliminating oil also reduces fire risks, increasing safety in various work environments.

Types of Oil-Free Compressors Available

Oil-free piston compressors are the most common type, using special self-lubricating piston rings made of Teflon or carbon. They feature simple construction, high efficiency for small to medium applications, and affordable prices, making them ideal for workshops and home use.

Scroll compressors stand out for their exceptionally quiet operation and smooth air delivery using two spirals — fixed and orbiting. This technology provides high reliability without oil in the compression chamber, making them ideal for low-noise environments.

Oil-free screw compressors use two coaxial helical rotors that compress air without contact. Synchronization is achieved via precision gears separated from the compression chamber, often with a water injection system. These energy-efficient devices deliver high output under full load.

Centrifugal compressors (turbo compressors) are high-performance, multi-stage compressors using a rapidly spinning impeller. Naturally oil-free, they are used in industries with very high compressed air demand. Oil-free vane compressors employ self-lubricating vanes, offering compact design and consistent airflow.

Professional Solutions in PATON’s Oil-Free Compressor Range

PATON, a leading manufacturer of welding equipment, also offers oil-free compressors as part of a comprehensive range for the welding industry. They provide solutions combining high reliability with clean air, essential for joint preparation and finishing work.

Although PATON specializes in inverter welders (MMA, MIG/MAG, TIG), their range also includes oil-free air compressors for powering pneumatic tools, blow-off tasks, and supporting ventilation/extraction systems. PATON products stand out with a warranty of up to 5 years and compliance with strict EU directives, ensuring safety and stable operating parameters.

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)