Air compressors are advanced mechanical devices designed to generate compressed air by increasing pressure and reducing volume. They are an essential component of workshops, industrial facilities, and households, providing a reliable source of pneumatic energy. Thanks to their versatility and efficiency, air compressors are used in countless technological processes and everyday tasks.

Where Are Air Compressors Used?

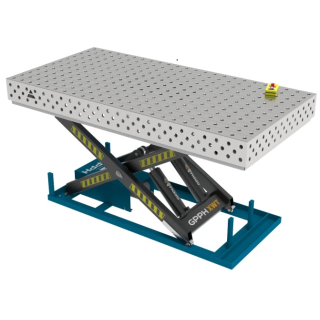

Automotive and industrial workshops use compressors to power a wide range of pneumatic tools, including impact wrenches, grinders, pneumatic hammers, and paint guns. In manufacturing industries, compressed air drives production lines, automation systems, and material processing machinery.

Construction and renovation require compressors to operate tools such as pneumatic drills, nail guns, and sandblasting equipment. Gas stations and tire service centres use compressors for inflating tires and servicing equipment.

In households, compressors are useful for inflating car tires, air mattresses, pools, and for painting and maintenance tasks. Specialized applications include medical and dental fields, where clean, oil-free compressed air is required, as well as irrigation systems in agriculture.

Air compressors in welding support the entire process — they cool tools and power sources, supply pneumatic grinders, sandblasters, and hammers, and facilitate preparation and finishing of joints. Compressed air is used to clean surfaces before welding and remove slag afterward, improving weld quality. It is also essential for workstation ventilation, powering fume extraction, and supplying clean air to breathing apparatuses, enhancing welder safety, especially in confined spaces.

Benefits of Air Compressors

Versatility and efficiency are key advantages of air compressors. A single device can power multiple pneumatic tools, significantly increasing work efficiency and reducing operating costs. High performance allows generating pressures from 6 to 14 bar, providing sufficient power for demanding applications.

Operational safety distinguishes pneumatic tools from electrical alternatives — no sparking reduces fire risk in hazardous environments. Precision and control are enhanced through accurate pressure and airflow regulation.

Energy efficiency of modern compressors translates to operational savings, while durable construction ensures long-lasting, reliable performance. Variety of sizes — from compact portable units to large stationary systems — allows users to choose the right equipment for their needs.

How to Maintain Your Equipment

Regular maintenance of compressors includes checking and replacing air filters, draining condensate from tanks, and inspecting pneumatic connections for leaks. Professional technical inspections ensure operational safety, optimal efficiency, prolong equipment life, and minimize the risk of breakdowns.

Overview of Available Types of Compressors

Piston compressors are the most common type, known for reliability and simple construction, ideal for small and medium workshops. Screw compressors are quieter and highly efficient, particularly valued in industrial applications requiring continuous operation.

Oil-free compressors produce clean, oil-free air necessary for the food, pharmaceutical, and medical industries. Portable models provide mobility and independence from fixed installations, while stationary compressors offer maximum efficiency and tank capacity.

Power options include mains-powered units (230V/400V) and battery-operated compressors, which ensure full mobility and energy independence in the field.

PATON – Comprehensive Solutions for Professionals

PATON is a leading manufacturer of welding equipment and distributor of a wide range of machinery and tools. The company offers not only advanced welders but also a **complete range of supplementary tools**, including air compressors as part of its workshop equipment offering.

Main PATON product range includes MMA welders, MIG/MAG welders, TIG welders, and multiprocessing machines, all featuring modern IGBT technology with digital control. The MINI series is designed for home users, STANDARD series for professional workshops, and PRO series for heavy industry.

Unique advantage of PATON — high duty cycle up to 70% or 100% (PowerMIG-400-15-4-400V). CE certification and compliance with EU directives guarantee the highest safety standards.

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)