-

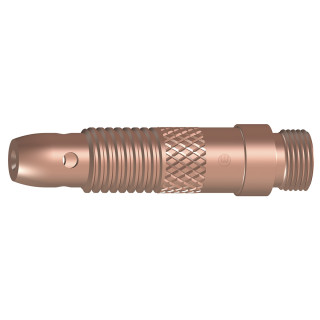

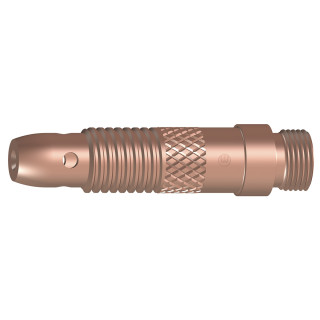

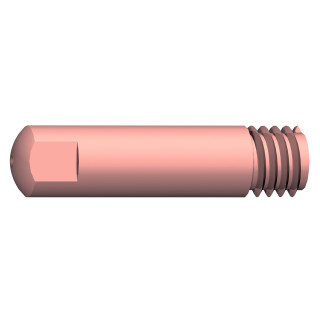

- 37 грн

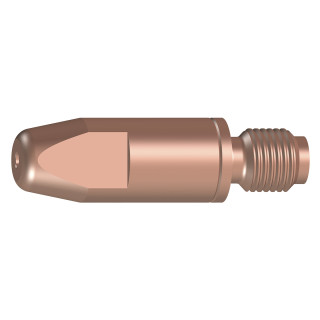

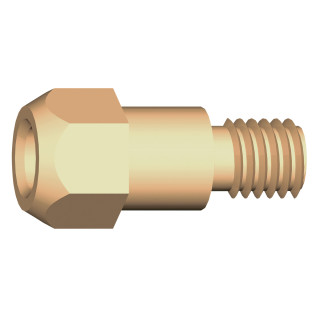

- Wire diameter 1,0 мм

- Length 25 мм

- Product material Electrolytic copper (E-Cu)

- Carving М6

- Diameter 6,0 мм

-

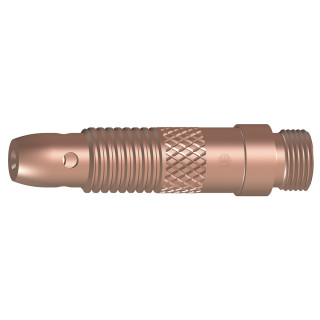

- 37 грн

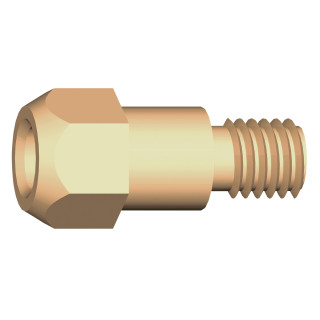

- Wire diameter 0,8 мм

- Length 25 мм

- Product material Electrolytic copper (E-Cu)

- Carving M6

- Diameter 6,0 мм

-

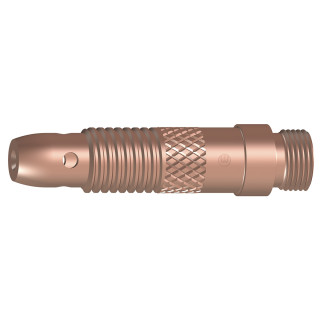

- 37 грн

- Wire diameter 0,6 мм

- Length 25 мм

- Product material copper (E-Cu)

- Carving M6

- Diameter 6,0 мм

-

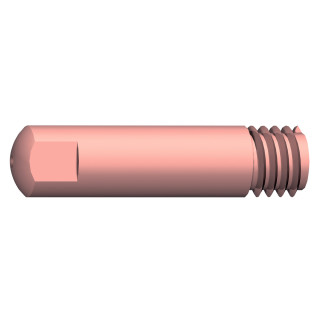

- 46 грн

- Wire diameter 1,0 мм

- Length 28 мм

- Carving M6

- Diameter 8,0 мм

- Inner diameter E-Cu (electrolytic copper)

-

- 46 грн

- Wire diameter 0,8 мм

- Length 28 мм

- Product material E-Cu (electrolytic copper)

- Carving M6

- Diameter 8,0 мм

-

- 46 грн

- Wire diameter 1,2 мм

- Length 28 мм

- Product material E-Cu (electrolytic copper)

- Carving M6

- Diameter 8,0 мм

-

- 63 грн

- Threaded part length 10 мм

- Wire diameter 1,2 мм

- Length 30 мм

- Product material electrolytic copper (E-Cu)

- Carving M8

-

- 63 грн

- Threaded part length 10 мм

- Length 30 мм

- Product material E-Cu (electrolytic copper)

- Carving M8

- Diameter 0,8 мм

-

- 63 грн

- Threaded part length 10 мм

- Wire diameter 1,6 мм

- Length 30 мм

- Product material electrolytic copper (E-Cu)

- Carving M8

-

- 63 грн

- Wire diameter 1,0 мм

- Length 30 мм

- Product material electrolytic copper (E-Cu)

- Carving M8

- Diameter 10 мм

-

- 67 грн

- Wire diameter 1,0 мм

- Length 28 мм

- Product material E-Cu (electrolytic copper), with special treatment for aluminum (Alu)

- Carving M6

- Diameter 8,0 мм

-

- 67 грн

- Wire diameter 0,8 мм

- Length 28 мм

- Product material E-Cu (electrolytic copper), with special treatment for aluminum (Alu)

- Carving M6

- Diameter 8,0 мм

-

- 67 грн

- Wire diameter 1,2 мм

- Length 28 мм

- Product material E-Cu (electrolytic copper), with special treatment for aluminum (Alu)

- Carving M6

- Diameter 8,0 мм

-

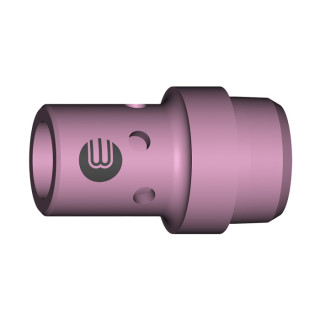

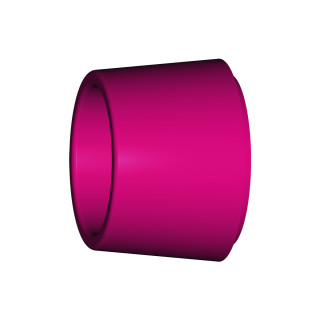

- Length 47,0 мм

- Product material high-temperature ceramics

- Inner diameter 8 мм

-

- Length 47,0 мм

- Product material high-temperature ceramics

- Inner diameter 11 мм

-

- Length 47,0 мм

- Product material high-temperature ceramics

- Inner diameter 12,5 мм

-

- Length 47,0 мм

- Product material high-temperature ceramics

- Inner diameter 16 мм

-

- Length 47,0 мм

- Product material high-temperature ceramics

- Inner diameter 6,5 мм

-

- Length 47,0 мм

- Product material high-temperature ceramics

- Inner diameter 9,5 мм

-

- Threaded part length 10 мм

- Length 30 мм

- Product material E-Cu (electrolytic copper), with special processing for aluminum (Alu)

- Carving M8

- Diameter 1,0 мм

-

- Threaded part length 10 мм

- Length 30 мм

- Product material E-Cu (electrolytic copper), with special processing for aluminum (Alu)

- Carving M8

- Diameter 0,8 мм

-

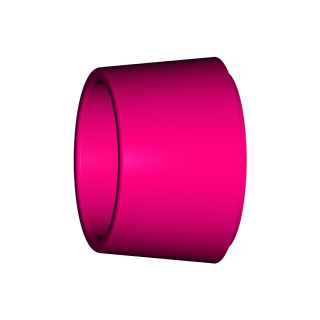

- Length 42,0 мм

- Product material high-temperature ceramics

- Inner diameter 11,0 мм

-

- Length 42,0 мм

- Product material high-temperature ceramics

- Inner diameter 6,5 мм

-

- 85 грн

- Product material Teflon/plastic, resistant to high temperatures and aggressive environments

-

- Length 42,0 мм

- Product material high-temperature ceramics

- Inner diameter 9,5 мм

-

- Length 42,0 мм

- Product material high-temperature ceramics

- Inner diameter 12,5 мм

-

- Length 42,0 мм

- Product material high-temperature ceramics

- Inner diameter 19,5 мм

-

- Length 42,0 мм

- Product material high-temperature ceramics

- Inner diameter 8,0 мм

-

- Threaded part length 10 мм

- Length 30 мм

- Product material E-Cu (electrolytic copper), with special processing for aluminum (Alu)

- Carving M8

- Diameter 1,2 мм

-

- 91 грн

- Wire diameter 1,0 мм

- Length 25 мм

- Product material CuCrZr (copper with chromium and zirconium)

- Carving M6

-

- 91 грн

- Wire diameter 1,2 мм

- Length 28 мм

- Product material CuCrZr (copper with impurities of chromium and zirconium)

- Carving M6

- Diameter 8,0 мм

-

- Compatibility ABIPLAS CUT 71 HF/ABIPLAS CUT 71 HF MT

-

- 104 грн

- Threaded part length 10 мм

- Wire diameter 1,6 мм

- Length 30 мм

- Product material CuCrZr (copper with chromium and zirconium additives)

- Carving M8

-

- 104 грн

- Threaded part length 10 мм

- Wire diameter 1,0 мм

- Length 30 мм

- Product material CuCrZr (copper with chromium and zirconium additives)

- Carving M8

-

- 104 грн

- Threaded part length 10 мм

- Wire diameter 1,2 мм

- Length 30 мм

- Product material CuCrZr (copper with chromium and zirconium additives)

- Carving M8

-

- 104 грн

- Threaded part length 10 мм

- Wire diameter 0,8 мм

- Length 30 мм

- Product material CuCrZr (copper with chromium and zirconium additives)

- Carving M8

-

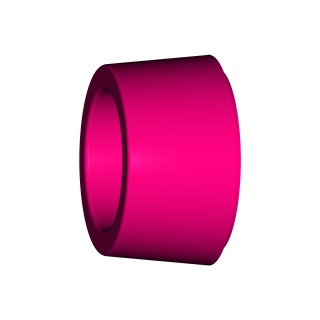

- Length 50,0 мм

- Product material high-temperature ceramics

- Inner diameter 19,5 мм

-

- Length 76,0 мм

- Product material high-temperature ceramics

- Inner diameter 9,5 мм

-

- Length 76,0 мм

- Product material high-temperature ceramics

- Inner diameter 8,0 мм

-

- Length 76,0 мм

- Product material high-temperature ceramics

- Inner diameter 11,0 мм

-

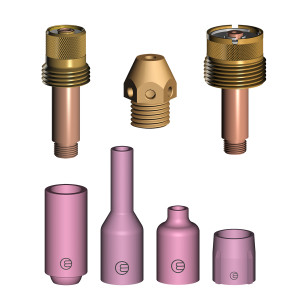

- 113 грн

- Material brass or copper alloy with high thermal conductivity

- Leingth 52 мм

- Diameter 0,5 мм

-

- 113 грн

- Material brass or copper alloy with high thermal conductivity

- Leingth 52 мм

- Diameter 3,2 мм

-

- 113 грн

- Material brass or copper alloy with high thermal conductivity

- Leingth 52 мм

- Diameter 1,2 мм

-

- 113 грн

- Material brass or copper alloy with high thermal conductivity

- Leingth 52 мм

- Diameter 2,0 мм

-

- 113 грн

- Material brass or copper alloy with high thermal conductivity

- Leingth 52 мм

- Diameter 4,0 мм

-

- 113 грн

- Material brass or copper alloy with high thermal conductivity

- Leingth 52 мм

- Diameter 2,4 мм

-

- Compatibility ABIPLAS CUT 111 HF, ABIPLAS CUT 111HF MT

-

- Length 48,0 мм

- Product material high-temperature ceramics

- Inner diameter 19,5 мм

-

- Length 34,0 мм

- Product material high-temperature ceramics

- Inner diameter 24,0 мм

-

- Length 47,0 мм

- Product material high-temperature ceramics

- Inner diameter 9,5 мм

-

- Length 48,0 мм

- Product material high-temperature ceramics

- Inner diameter 12,5 мм

-

- Length 48,0 мм

- Product material high-temperature ceramics

- Inner diameter 16,0 мм

-

- Length 76,0 мм

- Product material high-temperature ceramics

- Inner diameter 8,0 мм

-

- Length 76,0 мм

- Product material high-temperature ceramics

- Inner diameter 9,5 мм

-

- Length 76,0 мм

- Product material high-temperature ceramics

- Inner diameter 11,0 мм

-

- Compatibility ABIPLAS CUT 111 HF, ABIPLAS CUT 111HF MT

-

- Compatibility ABIPLAS CUT 71 HF, ABIPLAS CUT 71 HF MT

-

- Length 52,0 мм

- Product material copper or brass alloy

- Inner diameter 12,0 мм

-

- 228 грн

- Internal thread M6

- Length 35 мм

- Product material Brass or copper alloy

- External thread M12

-

- Compatibility ABIPLAS CUT 111 HF, ABIPLAS CUT 111HF MT

-

- 294 грн

- Product material Teflon/plastic, resistant to high temperatures and aggressive environments

-

- Length 63,5 мм

- Product material electroplated copper alloy

- Diameter 12,5 мм

-

- 350 грн

- Length 27 мм

- Product material Brass or copper alloy

- Carving M10

- Internal thread M8

-

- Length 76,0 мм

- Product material copper or copper alloy with heat-resistant coating

- Diameter 16,0 мм

-

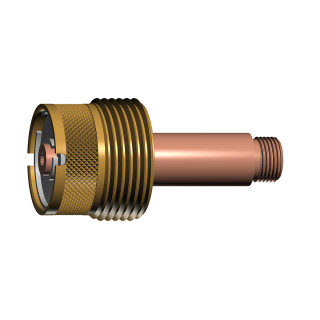

- 375 грн

- Internal thread M8

- Length 53 мм

- Product material Brass

- External thread М12

-

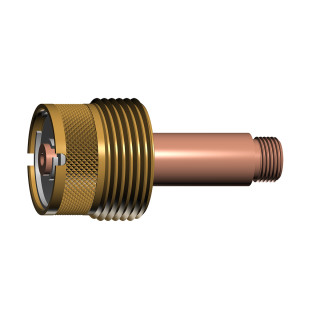

- 375 грн

- Internal thread M6

- Length 52 мм

- Product material Brass

- External thread М15

-

- 375 грн

- Internal thread M8

- Length 52 мм

- Product material Brass or copper alloy

- External thread M16

-

- 375 грн

- Internal thread M6

- Length 51 мм

- Product material Brass or copper alloy

- External thread M14

-

- Material Steel

- Length 340 мм

- Diameter 4,5 мм

- Inner diameter 1,5 мм

-

- 390 грн

- Length 28 мм

- Product material brass or copper alloy

- External thread M10

-

- Length 340 мм

- Diameter 4,5 мм

- Inner diameter 2,5 мм

-

- Length 84,0 мм

- Product material copper or copper-nickel alloy with heat-resistant coating

- Diameter 16,0 мм

-

- 435 грн

- Length 440 мм

- Diameter 4,5 мм

- Inner diameter 2,0 мм

-

- Material Steel

- Length 440 мм

- Diameter 4,5 мм

- Inner diameter 1,5 мм

-

- Length 52 мм

- Product material Copper with electroplating (nickel or zinc)

- Diameter 20 мм

- Inner diameter 12,0 мм

-

- Length 54 мм

- Product material Galvanized copper (nickel or zinc)

- Diameter 20 мм

- Inner diameter 12,0 мм

-

- 497 грн

- Length 32,5 мм

- Product material Heat-resistant plastic

-

- 502 грн

- Length 69 мм

- Product material Galvanized metal (galvanized)

- Carving M14

- Diameter 22 мм

- Inner diameter 18 мм

-

- Material Steel

- Length 540 мм

- Diameter 4,5 мм

- Inner diameter 1,5 мм

-

- Length 70 мм

- Product material Steel with anti-corrosion coating

- Carving M6

- Diameter 22,0 мм

- Inner diameter 15,0 мм

-

- Length 67 мм

- Product material Copper

- Carving M12

- Diameter 22,0 мм

- Inner diameter 14,0 мм

-

- Length 70 мм

- Diameter 22 мм

- Inner diameter 16,0 мм

-

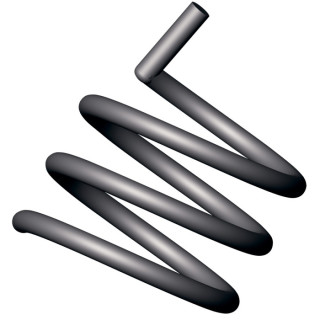

- 561 грн

- Length 540 мм

- Product material steel spiral with non-stick polymer coating

- Diameter 4,5 мм

- Inner diameter 2,0 мм

-

- Compatibility ABIPLAS CUT 71 HF, ABIPLAS CUT 71 HF MT

-

- 644 грн

- Length 66 мм

- Product material copper alloy

- Carving M20

- Inner diameter 14,5 мм

-

- Product material copper alloy

- Diameter 2,0-2,4 мм

-

- Product material copper alloy

- Diameter 3,2 мм

-

- Product material copper alloy

- Diameter 4,0 мм

-

- Product material copper alloy

- Diameter 0,5-1,2 мм

-

- Product material copper alloy

- Diameter 1,6 мм

-

- Length 72 мм

- Product material Steel with anti-corrosion coating

- Carving M6

- Diameter 25,0 мм

- Inner diameter 17,0 мм

-

- 633 грн759 грн

- Length 72 мм

- Product material copper + electroplating

- Carving M12

- Inner diameter 18 мм

-

- Compatibility ABIPLAS CUT 71 HF, ABIPLAS CUT 71 HF MT

-

- Compatibility ABIPLAS CUT 111 HF, ABIPLAS CUT 111HF MT

-

- 1208 грн

- Internal/external size 2,7 мм /4,7 мм

- Length 350 мм

-

- 1099 грн1220 грн

- Length 85 мм

- Product material chrome-plated copper

- Diameter 28,0 мм

- Inner diameter 16,0 мм

-

- Product material copper alloy

- Diameter 3,2 мм

-

- Product material copper alloy

- Diameter 4,0 мм

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)