Specification

| Max inlet pressure, MPa | 1 |

| Max working gas pressure, MPa | 0,07 |

| Weight, kg | 0,6 |

Show all specifications

Description

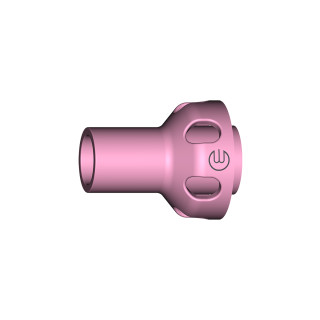

Device for saving and optimizing the flow of carbon dioxide/argon

For arc welding in protective gases, reducers with a working pressure of up to 10 kgf/cm2 are used. When welding is stopped, excess gas pressure is created in the sleeve between the reducer and the welding machine (usually 3.5-6 kgf/cm2). After welding is continued, this excess gas volume is instantly discharged into the atmosphere. In this case, the amount of excess gas can be 6 times higher than at the time of welding. At the same time, for optimal protection of the weld pool, a maximum pressure of 1.0 kgf/cm2 is required at a flow rate of 25 l/min. The reducer attachment ― “DM Optimizer” will help to avoid these losses

- Installed on the output fitting of the reducer;

- Saves up to 50% of the protective gas;

- Reduces the frequency of changing cylinders;

- Reduces costs for transporting cylinders to the gas station;

- Saves money on gas purchases

Provides:

- Optimal flow of shielding gas from the first seconds;

- No turbulent surge at the beginning of welding;

- Twice as many seams for the same amount of gas.

Testimonials

Specification

| Max inlet pressure, MPa | 1 |

| Max working gas pressure, MPa | 0,07 |

| Weight, kg | 0,6 |

DM Optimizer

Code: 045.000.00

In Stock

- 1200 грн

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)

-320x320.jpg)